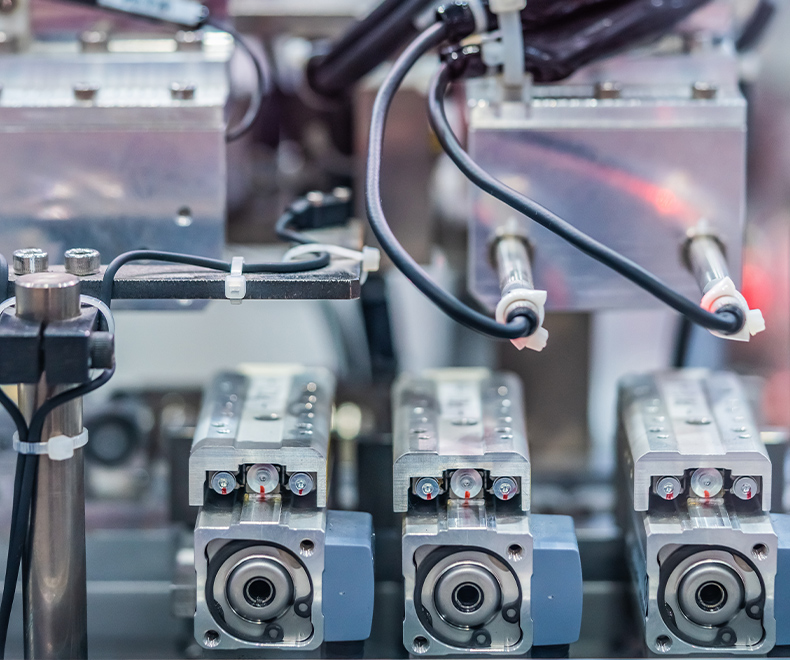

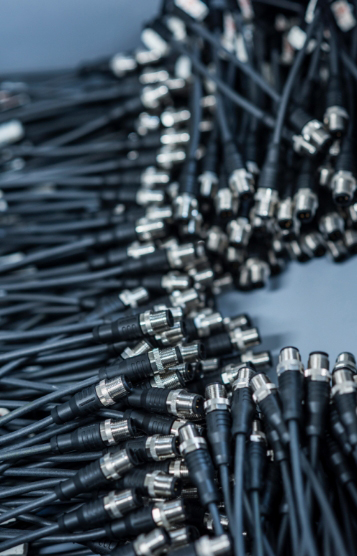

Kabelkonfektion

nach modernsten

Arbeitsmethoden

Als Systemlieferant mit einer jahrelangen Erfahrung

bieten wir verschiedenen Industriebranchen ein

umfangreiches Leistungsspektrum an.

Kabelkonfektion für PV-Anlagen und Solarparks

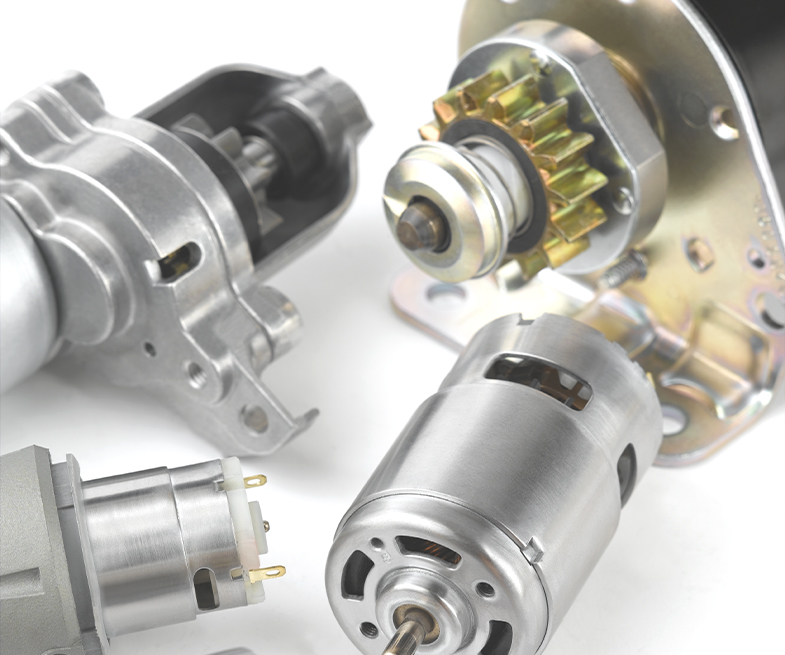

innovativ & flexibel:

unsere Mikroschalter

& Schnappschalter

Im breit gefächerten Produktprogramm unseres

Unternehmens zählen hochwertige Mikroschalter

zu den elementaren Bestandteilen.

Klasse Service &

beste Qualität

- das ist Sicatron

Im Bereich Kabelkonfektion bieten wir Ihnen von der

Konzeption eines Produktes über den ersten Prototypen

bis hin zur fertigen Serie die perfekte Kombination.

Haben Sie Fragen?

nehmen sie Kontakt

zu uns auf.

Gerne stehen wir Ihnen bei offenen Fragen zu uns

und unseren Leistungen zur Verfügung, denn Ihre

Wünsche sind uns wichtig!